https://www.blueskyreps.com/wp-content/uploads/2022/12/Monosnap-Nov-Phoenix-Surge-2022_PxCedits.pdf-2022-12-02-10-19-44.jpg

842

650

Robert Neumann

https://blueskyrepsliv.wpengine.com/wp-content/uploads/2020/03/logo-Blue-Sky-Reps.jpg

Robert Neumann2022-12-02 10:26:572022-12-05 14:15:14Phoenix Contact Surge Protection

https://www.blueskyreps.com/wp-content/uploads/2022/12/Monosnap-Nov-Phoenix-Surge-2022_PxCedits.pdf-2022-12-02-10-19-44.jpg

842

650

Robert Neumann

https://blueskyrepsliv.wpengine.com/wp-content/uploads/2020/03/logo-Blue-Sky-Reps.jpg

Robert Neumann2022-12-02 10:26:572022-12-05 14:15:14Phoenix Contact Surge ProtectionSOLUTIONS FOR PROCESS AUTOMATION

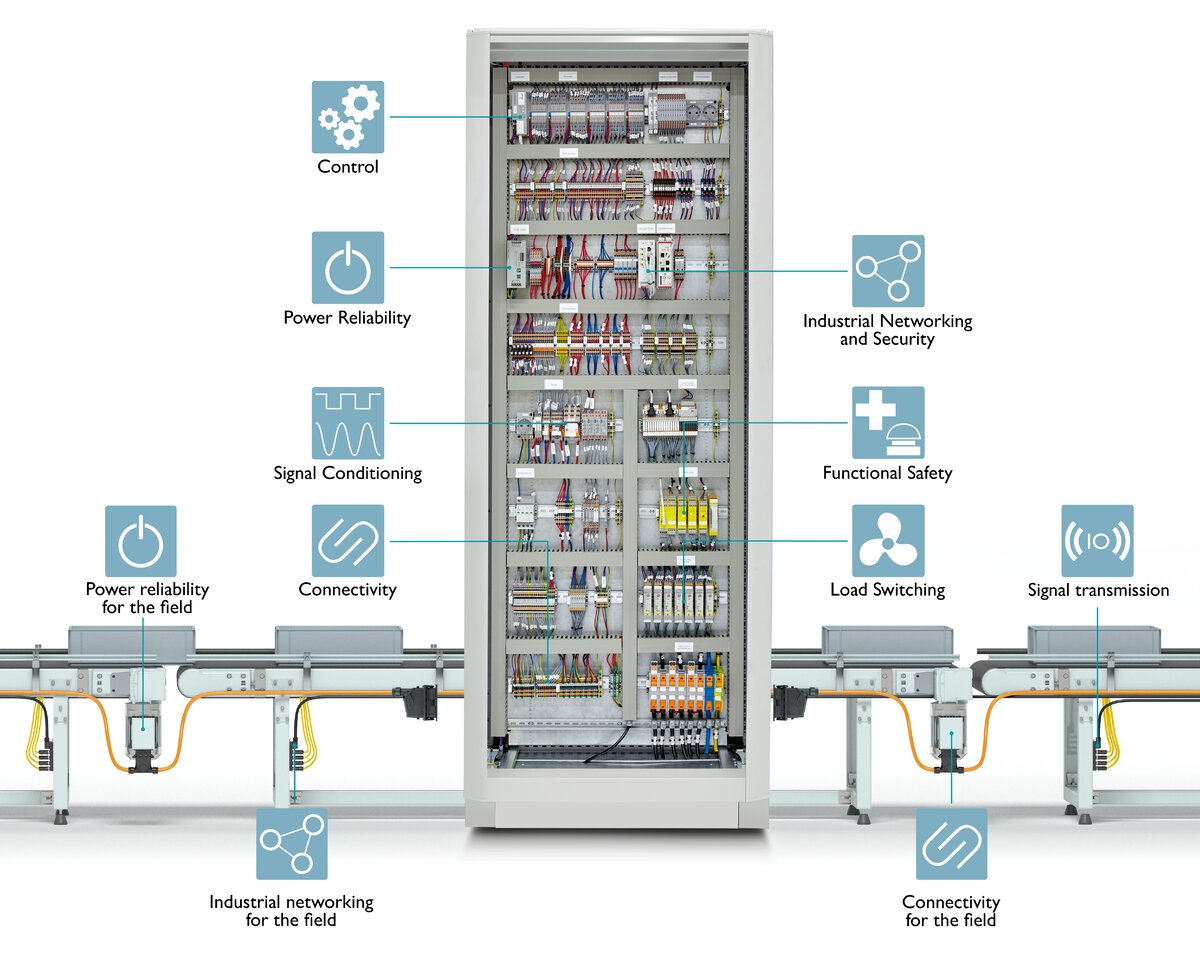

Phoenix Contact solutions are used wherever processes need to run automatically. This can be in industrial production facilities, in the field of renewable energy, in infrastructure, or for complex device connections. Our products are used wherever power or data flows are connected, distributed, and controlled. Your benefits go beyond the pure function: Our products help our partners to develop sustainable applications with more efficient processes and reduced costs.

Control

Backbone Infrastructure

Visualization

Network Security

Backbone Network

Control

Phoenix Contact has close ties with the machine building industry. We provide you with a comprehensive range of products and services for machine building

Your advantages

-

Consistent planning and documentation with complete digital data for all products.

-

Easy handling and reduced variety of parts with systematically designed products.

-

Scalable manufacturing solutions for customized processes.

Connect

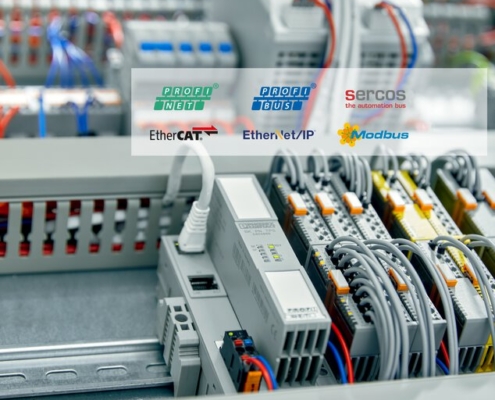

Remote Access | Ethernet Infrastructure | Signal Integrity

Cellular

Wireless I/O

Fiber Conversion

Managed & Unmanaged Ethernet

Wireless Ethernet

Signal Isolation Barriers

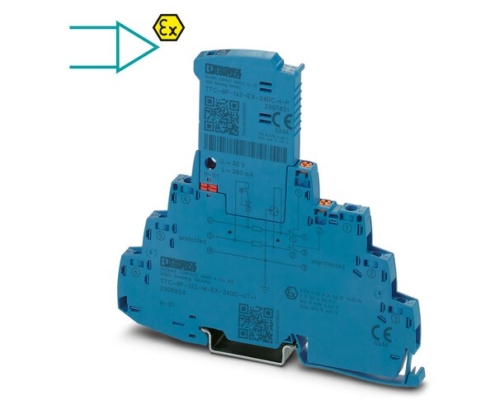

Communication & Data Protection

Hazardous & Non Hazardous Signal Protection

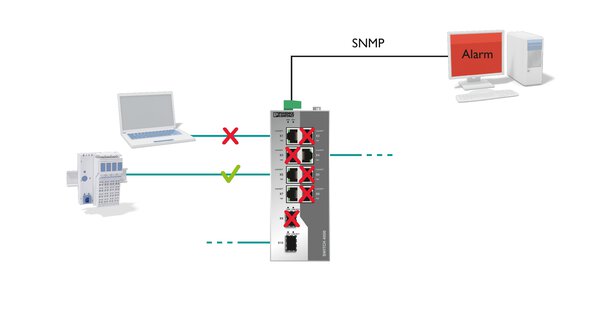

We make Ethernet Easy

When we say “We make Ethernet easy”, we are talking about controlling the complexity of high-performance Ethernet networks. Therefore, we have consistently designed our products with the knowledge, the tools, and the skills of the user in mind, the automation specialist.

Your advantages

-

Complete flexibility: Terminal blocks with different connection technologies can be freely combined.

-

Bridging and testing option with double function shaft.

-

Additional test option with integrated test points, eliminating the need for removing conductors or bridges.

PoE

I/O Mapping

Collect

Device Connectivity

HART over Wireless

HART mux

Consistent System Documentation

In large systems in the process industry, a huge amount of resources are dedicated to keeping system documentation up to date. Maintenance employees or external companies regularly inspect the production plant and document the changes identified through so-called red entries. The transfer of these red entries from paper lists to a P&I flow diagram often harbors the risk of transfer errors. As a result, manufacturer information cannot be assessed in the event of device discontinuation or product changes. Due to the constantly changing field device inventory in the production plant and the partially missing information, an inventory cannot be planned, which significantly complicates any necessary device replacements.

Digital system transparency

80% of systems in the process industry are equipped with digital, HART-compatible field devices. However, only 5% of these use digital signals.

We make it possible for you to retroactively tap HART data and provide the necessary field data in OPC UA format with no adverse effects. With this additional smart field device data, you benefit from digital system transparency – the so-called digital twin. With this transparency, maintenance, upkeep, and availability can be improved significantly.

PROFIBUS PA

PROFIBUS DP

Digital twin in process automation. Easy comparison between As Planned and As Built

- Current, real data from the plant is available at all times with automatic as-built documentation.

- Tours for manually recording the installed HART field devices are no longer necessary due to the field devices being continuously connected.

- Rapid troubleshooting and the avoidance of downtimes in the event of manufacturer recalls, changes, or discontinuations with optimized inventories.

Your advantages

-

Fast and universal access to all sensors and data at the field and machine levels.

-

The ability to develop new business models, such as for sensor manufacturers or system integrators.

-

Scalable and customizable data collection solutions for greenfield and brownfield applications.

New Products

Photovoltaic Connectors

Modules & Inverters

EMC Filter

Protection against high-frequency interferance

STEP POWER

Power Supply for Building Automation

Smart Camera Box

for Video Surveillance

Charging Technology

for E-Mobility

Vertical Markets Served

Transportation

Electric Vehicle

Charging Infrastructure

Public Lighting

Tunnel Technology

Rail Transit

Industrial

Conventional Power Generation

Energy Storage Systems

Solar Power

Wind Power

Building Infrastructure

Marine

Offshore

Rudder Systems

Fire Detection Systems